Top 10 7.3L Power Stroke Tech Tips from the Experts

Jan 6th 2026

The 7.3L Power Stroke is widely regarded as one of the most durable diesel engines Ford ever put in a pickup. However, long service life doesn’t mean problem-free ownership. After decades of diagnosing real-world failures, a clear set of patterns has emerged—issues that repeatedly affect drivability, reliability, and longevity.

This guide outlines ten expert-backed 7.3L Power Stroke tech tips, focusing on proven maintenance strategies and upgrades that consistently deliver results. These aren’t theoretical fixes—they’re solutions backed by years of field experience and customer feedback.

1. Use the Correct Engine Oil—It Directly Affects Injectors

The 7.3L Power Stroke relies on engine oil pressure to actuate its HEUI injectors. Incorrect oil viscosity, poor-quality oil, or extended change intervals can lead to injector stiction, rough idle, hard starts, and power loss.

Expert Tip:

Use a high-quality 15W-40 (or 5W-40 in cold climates)

Maintain strict oil change intervals

Clean, stable oil equals consistent injector performance.

Related Links:

Motorcraft Replacement Oil Filter: https://www.riffraffdiesel.com/oil-filter-1994-2003-7-3l/

2. Upgrade the Cam Position Sensor Before It Leaves You Stranded

A failing cam position sensor (CPS) can cause sudden engine shutdown with no warning. If the tachometer does not move while cranking, the CPS is a prime suspect.

Recommended Upgrade:

Riffraff Diesel Upgraded Cam Position Sensor (1994–2003 7.3L): https://www.riffraffdiesel.com/cam-position-sensor-upgraded-cps-94-03-7-3l/

This improved CPS delivers a stronger, more stable signal than other replacements, plus upgraded technology, together helping eliminate one of the most common roadside failures.

3. Maintain Proper Fuel Pressure to Protect Injectors

Fuel pressure below specification may not trigger a diagnostic trouble code, but it will accelerate injector wear. The safe minimum under load is approximately 45 PSI.

Preventative Solution:

Fuel Bowl FPR Complete Rebuild Kit 99-03 7.3L Powerstroke: https://www.riffraffdiesel.com/fuel-bowl-fpr-complete-rebuild-kit-99-03-7-3l/

Stable fuel pressure dramatically extends injector life and improves throttle response.

4. Reduce Intake Restriction for Lower EGTs

The factory 7.3L intake system is restrictive, particularly on trucks that tow or run larger injectors. Excess restriction increases exhaust gas temperatures and reduces turbo efficiency.

Upgrade Recommendation:

Riffraff Diesel 6637 Intake Kit: https://www.riffraffdiesel.com/riffraff-diesel-6637-intake-kit/

This air filter kit improves airflow without compromising MAF accuracy or drivability.

5. Replace Oil-Soaked Intercooler Boots

Intercooler boot failures are often caused by oil contamination from the CCV system, not weak clamps. Oil reduces friction and allows boots to slip under boost.

Permanent Fix:

Complete CAC Intercooler Boot Kit 99-03: https://www.riffraffdiesel.com/complete-cac-intercooler-boot-kit-99-03/

94-97 Turbo Intake and Y Boot Kit: https://www.riffraffdiesel.com/riffraff-diesel-94-97-turbo-intake-and-y-boot-kit/

Cleaning the pipes and upgrading to reinforced silicone boots prevents repeat failures.

6. Clean and Upgrade Electrical Grounds

The 7.3L Power Stroke is extremely sensitive to voltage drop. Poor grounds can cause erratic sensor readings, injector misfires, hard starts, and unexplained trouble codes.

Best Practice:

Clean battery terminals and engine grounds

Upgrade ground cables where corrosion or resistance is present

Many “electrical” problems are simply grounding issues in disguise.

Related Links:

Positive Battery Terminal Clamp: https://www.riffraffdiesel.com/positive-battery-terminal-clamp/

Negative Battery Terminal Clamp: https://www.riffraffdiesel.com/negative-battery-terminal-clamp/

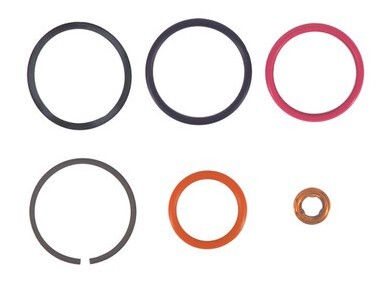

7. Replace Injector O-Rings at the First Sign of Cross-Contamination (or sooner)

Fuel in the oil or oil in the fuel indicates failing injector O-rings. Heat cycles and age degrade the factory seals over time.

Recommended Service Parts:

Alliant Injector O-Ring Kit – 7.3L Power Stroke: https://www.riffraffdiesel.com/alliant-injector-o-rings/

Replacing O-rings during injector service prevents catastrophic oil dilution.

8. Improve Exhaust Flow to Reduce Heat

The factory exhaust system restricts flow and traps heat, and the up pipes are prone for leaks. Excessive backpressure raises EGTs and strains the turbocharger, especially when towing. Exhaust leaks rob power and efficiency.

Upgrade Options:

MBRP 4” Exhaust Systems (Available via Riffraff Diesel):https://www.riffraffdiesel.com/mbrp-4-turbo-back-aluminized/

Riffraff Diesel Bellowed Stainless Up-pipe Kit 99.5-03: https://www.riffraffdiesel.com/riffraff-diesel-bellowed-stainless-up-pipe-kit-99-5-03/

Riffraff Diesel Bellowed Up-pipe Kit 94-Early 99: https://www.riffraffdiesel.com/riffraff-diesel-bellowed-up-pipe-kit-94-early-99/

Lower backpressure and no exhaust leaks, equals lower EGTs and improved turbo response.

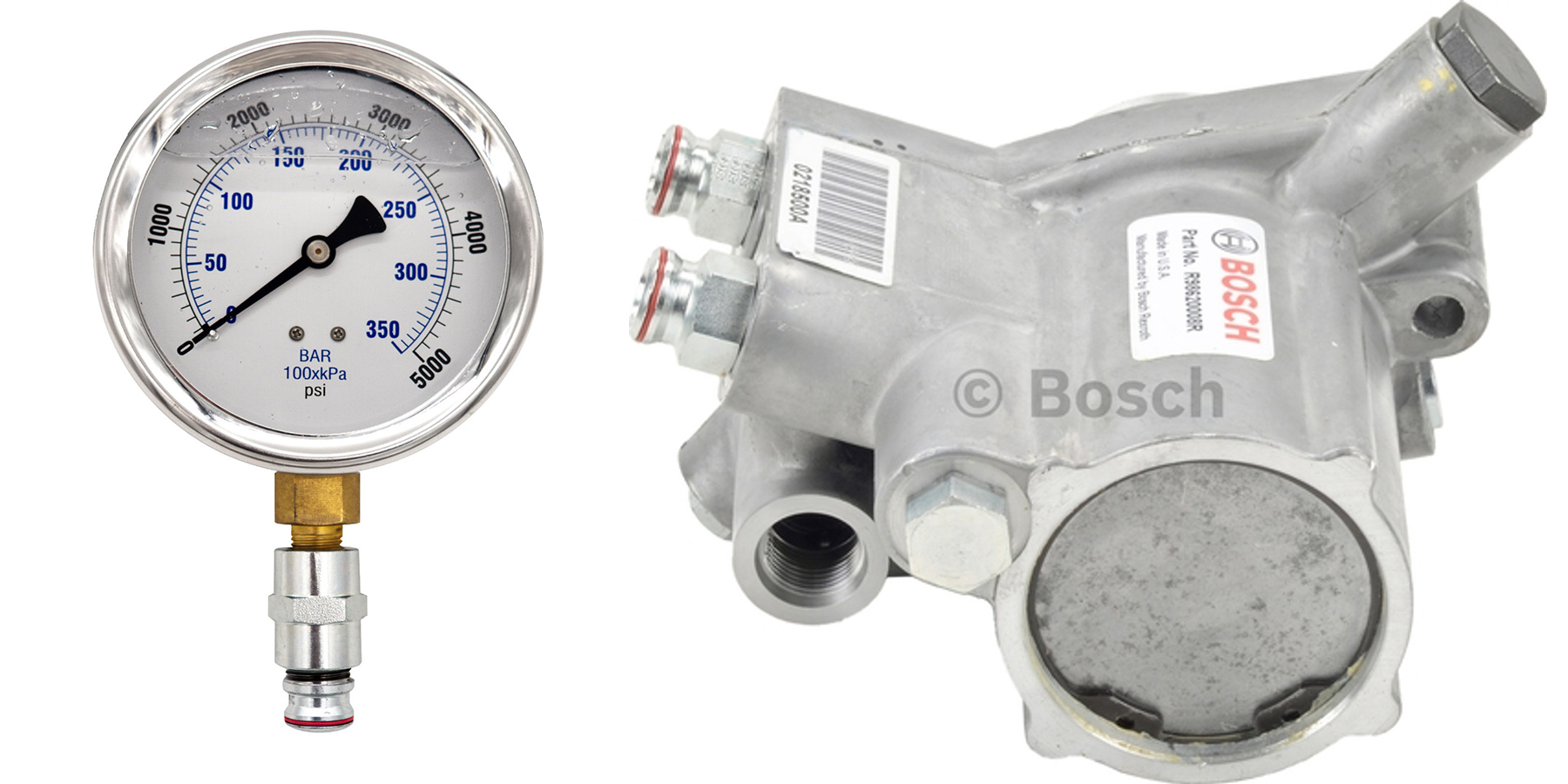

9. Diagnose the High-Pressure Oil System Correctly

Hot no-starts, long crank times, and low ICP readings are often related to high-pressure oil leaks or worn components.

Critical Components to Inspect:

High-pressure oil pump (HPOP)

IPR valve

Injection control pressure sensor

Accurate diagnosis prevents unnecessary parts replacement.

Related Links:

7.3L Powerstroke HPOP Failure: Symptoms, Diag and their Fixes (blog): https://www.riffraffdiesel.com/blog/73l-powerstroke-hpop-failure-symptoms-diag-and-their-fixes-/

Alliant Injection Pressure Regulator IPR 96-03: https://www.riffraffdiesel.com/alliant-injection-pressure-regulator-ipr-96-03/

ICP / EBP Pigtail Harness 94-07: https://www.riffraffdiesel.com/icp-ebp-pigtail-harness-94-07/

Injection Control Pressure ICP Sensor 97-03: https://www.riffraffdiesel.com/injection-control-pressure-icp-sensor-97-03/

HPOP JIC Line - Passenger Side Head 99-03: https://www.riffraffdiesel.com/hpop-jic-line-passenger-side-head-99-03/

HPOP JIC Line - Driver Side Head 99-03: https://www.riffraffdiesel.com/hpop-jic-line-driver-side-head-99-03/

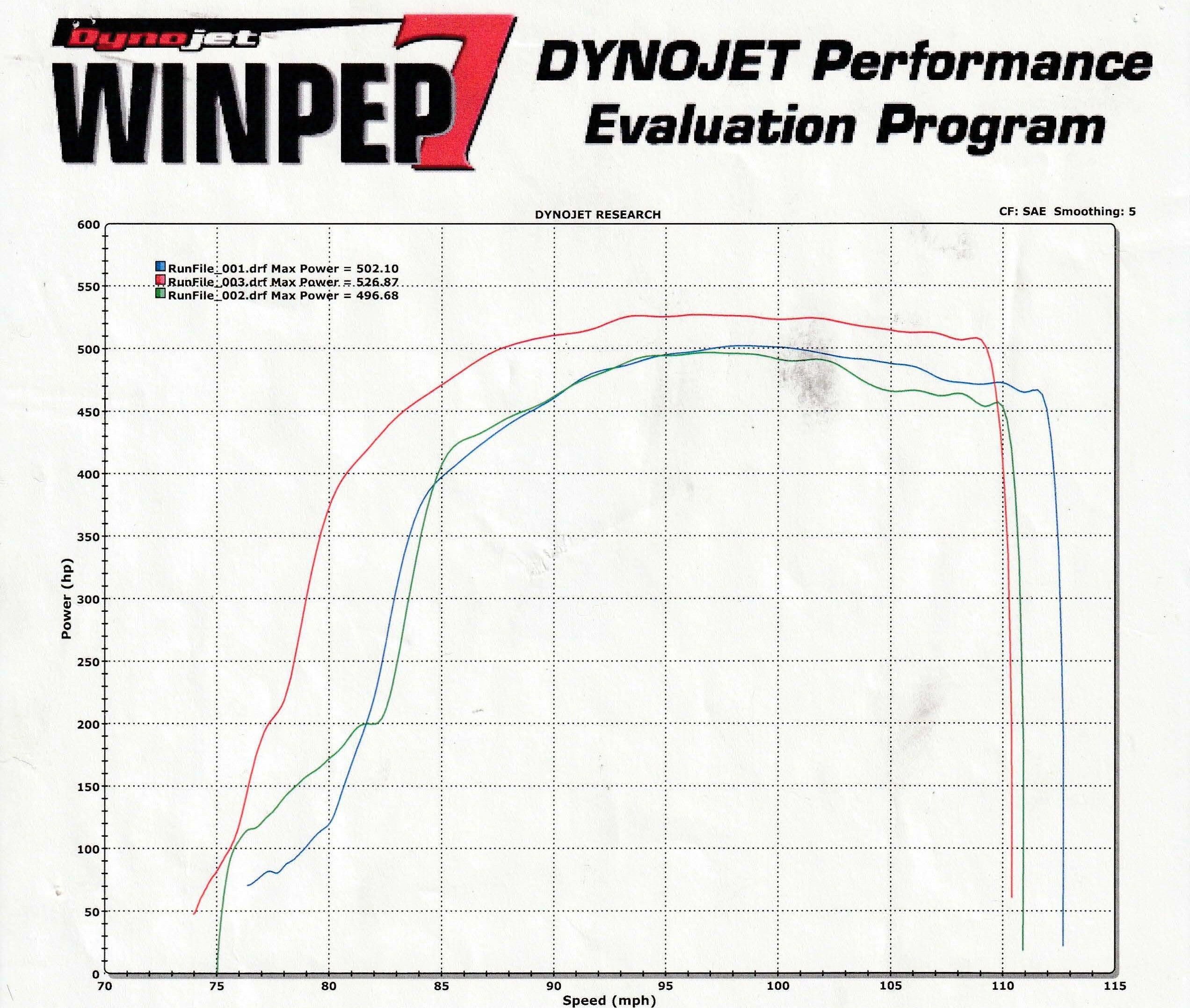

10. Reliability Always Comes Before Horsepower

The fastest way to shorten the life of a 7.3L Power Stroke is adding power before addressing known weak points. Stable fuel pressure, clean oil, solid sensors, and proper airflow should always come first.

Foundational Upgrades Include:

Fuel supply improvements

Oil filtration improvements

Intake and exhaust flow

Sensor reliability

Horsepower should be the final step—not the first.

Final Thoughts: Proven Fixes Keep the 7.3L Alive

The 7.3L Power Stroke doesn’t require gimmicks or shortcuts. It rewards owners who focus on fundamentals, preventative maintenance, and proven upgrades. Address these ten areas correctly, quickly address any other issues as they arise, and a properly maintained 7.3L will continue delivering dependable service well past 300,000 miles. For more worthy upgrades for efficiency and longevity, stay tuned to our blog or better yet, sign up for our newsletter for weekly tips and tricks (and zero spam).

For parts that solve real problems—not just symptoms—Riffraff Diesel remains the go-to source for 7.3L Power Stroke reliability.