7.3L Cam Position Sensor, An In Depth Look - How It Works, Wiring Diagrams, Voltage Readings, and More

Nov 30th 2025

The Camshaft Position Sensor (CPS) on the 7.3L Powerstroke is a Hall-effect sensor mounted on the front of the engine, positioned just above the harmonic balancer near the 11 o’clock orientation. This sensor reads the passing windows and tabs on the camshaft trigger wheel as they move through its magnetic field, producing a digital square-wave signal. The Powertrain Control Module (PCM) uses this signal to determine precise engine RPM, camshaft position, and piston synchronization. Accurate CPS data is essential for injection timing, engine start-up, and overall drivability on all 1994–2003 7.3L Powerstroke applications.

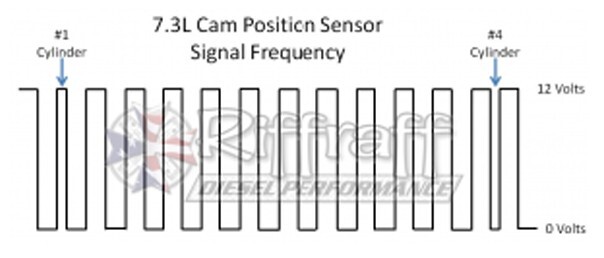

The cam wheel has 24 windows built into it. These windows are essentially gaps and the remaining material is the target that the sensor see’s. The PCM can tell what position the engine is in because the cylinder #1 and Cylinder #4 windows are narrower and wider than the other windows. This allows the PCM to determine the exact rotational position of the engine based on the firing order of 12734568.

The CPS takes an input signal of 5 volts DC or better known as Vehicle Reference Voltage (VREF) which is sent out by the PCM. The CPS converts the 5 vdc signal input into a 12 vdc signal that gets returned to the PCM. (See Below). When the cam wheel gaps are in front of the sensor it will read a 0 volt output. When the targets are in front of the sensor, you will get a 12 volt output. The frequency of the signal is anywhere from 100 to 700 Hz.

CPS Failure used to be a serious problem. Cam sensors were known for leaving many 7.3L owners stranded in a parking lot or driveway. The engine would run fine, be shut off, but wouldn’t start again when a CPS failed. There was no warning or anything, just cranking with no start. The PCM was in fact doing what it was supposed to do. It wasn’t detecting a signal as to where the engine was in the rotation and it did not know how fast it was going, so it would not send an injector signal to the IDM. Owners or pre-2002 trucks could watch the tachometer when cranking and if they did not see the tach needle moving, they had a pretty good indication that the CPS had failed. Owners of 2002-2003 7.3L trucks did not have a way to tell since the instrument cluster was a hybrid cluster and didn’t utilize the same circuitry as the older trucks.

Ford issued a safety recall (07S57) of the CPS after many failures and urging from owners and the National Highway Safety Administration. The original sensor P/N F7TZ12K073A was black in color and had a zinc or gold colored bracket. The “new” Grey CPS that Ford redesigned and installed in the engine was P/N F7TZ12K073B and has a silver bracket. Both are similar in looks, however, the original black one has a larger diameter magnetic pickup area. The new grey CPS was soon found to have deficiencies that many owners found less than desirable. On many trucks, there was a noticeable miss at idle that could be felt. Other issues with the new CPS was the failure of Injector #8 when running a Cylinder Contribution Test (CCT). Many injectors were misdiagnosed and replaced when DTC P0284 was thrown while running a CCT. Many owners of 7.3L trucks were replacing the grey CPS with the original black ones and finding the truck just ran better with the original designed CPS installed. It was common practice for an owner to carry a spare CPS and the tools required to replace it in order to get the smoother idle and better MPG offered by the black one.

Ford also introduced P/N F4TZ12K073C into the market for the 95-97 model year 7.3L’s as an improved model CPS. This sensor is dark grey in color and also has a silver bracket. Owners of the 9903 trucks found that this sensor offered better idle and MPG increases when they ran it in their newer trucks. This sensor is widely available as is the grey one and the prices are downright affordable compared to the original price on the black CPS. Here is a comparison of the three different sensors side by side.

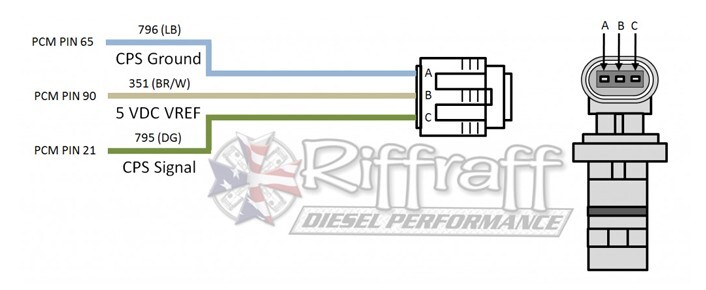

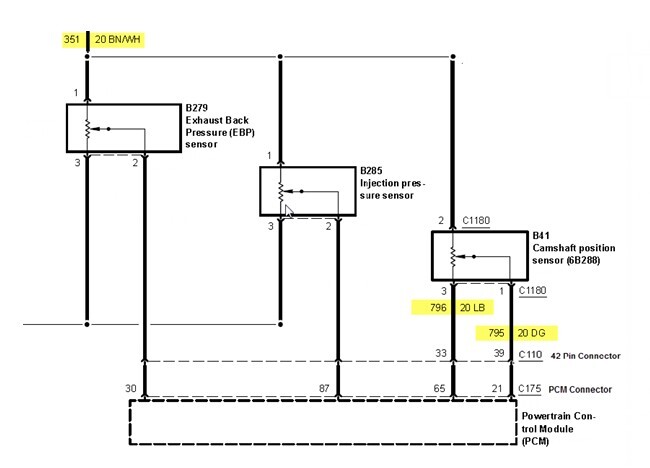

The CPS Wiring is pretty basic. There are three wires in the sensor connector that allow it to work properly. The circuit consists of a CPS Ground, 5 VDC (VREF) Signal & the CPS 12 VDC Return Signal. (See Below)

Troubleshooting CPS Issues

CPS Diagnostic Trouble Codes (DTC’s) are as follows:

- P0340 = CPS Sensor Malfunction

- P0341 = CPS Sensor Circuit Performance

- P0344 = CPS Sensor Circuit Intermittent

Diagnosis of the CPS is pretty straightforward. Using a diagnostic tool like AutoEnginuity Total Ford Enhanced Bundle select Engine RPM and watch the readout as you crank the engine over. If you get an RPM reading, your CPS is more than likely working correctly. If you do not get the RPM reading, you need to perform a continuity check on the wiring to ensure you don’t have an open circuit. You can disconnect the PCM plug and use the pins called out in the diagram above to verify continuity. Once you have verified that the wires are not open, you can reconnect the connector to the PCM and verify you get 5 VDC with the key on, engine off on circuit 351. If your wiring checks out, you are pretty safe to say that the CPS has failed and you need to replace it.

Aftermarket CPS replacement is an option. Many have complained that the aftermarket CPS’s offered by Amazon or the or other similar mass retailers do not last as long and fail sooner than expected. It is recommended that only OEM CPS’s you only use Ford/Motorcraft or International-branded parts. To buy a replacement or a spare Cam Position Sensor for your 7.3L remember Riffraff Diesel stocks many of the most needed OEM parts and can get other OEM parts delivered to you at a discounted price that will make your local dealership blush.

Related Parts Links:

Motorcraft Cam Position Sensor 1994-2003: https://www.riffraffdiesel.com/cam-position-sensor-cps-94-03/

Riffraff Diesel Cam Position Sensor 1994-2003: https://www.riffraffdiesel.com/cam-position-sensor-upgraded-cps-94-03-7-3l/

CPS Harness Pigtail 1994-2003 7.3 Powerstroke: https://www.riffraffdiesel.com/cps-harness-pigtail-94-03/

CPS O-ring 1994-2003: https://www.riffraffdiesel.com/cps-o-ring/