The VGT Turbo: How it works; How it fails; How to prevent failures and fix the issues you already have.

Posted by Adam Blattenberg on Sep 27th 2025

When Ford released the 6.0L Powerstroke back in 2003, it was a game-changer. The engine outperformed any diesel on the market in both throttle response and peak horsepower. A big reason for this was the engine’s new Variable Geometry Turbocharger (VGT). The 6.0 was the first diesel engine to use this new turbo technology in the US. The VGT is a variable rate turbo; it utilizes vanes within the turbine side of the housing to reduce spool times, making it extremely responsive. By adjusting these vanes, exhaust gases are directed at the turbine wheel at varying velocities. Crank up the velocity at low RPM for great throttle response and open it back up once the truck is underway, for sustained power. VGTs would very quickly become the standard for diesel engines.

Now as with any new technology, the first usages come with problems and bugs to be worked out. That’s life. The 6.0L’s VGT had its share of problems, too. But the best news? They’re very fixable, and the turbo can be made very reliable for the long haul. Here’s a list of turbo-related issues on the 6.0, their symptoms, and their fixes.

As always these are the most common issues we’ve seen over the years. It's not necessarily an all-inclusive list, your issues may differ. Either way, this’ll get you pointed in the right direction.

1. VGT Unison Ring Sticking

The Unison Ring ties all the vanes together, and allows the VGT solenoid to control their operation.

Cause: Carbon buildup and soot accumulation in the unison ring and vanes. The 6.0’s EGR system and CCV oil mist contribute heavily to this.

Symptoms:

- Low boost or lag

- Overboost (vanes stuck closed), causing P0234 DTC

- Fluttering or surging under load

- Turbo bark or loud whistle at odd times

Fix:

- Pull turbo, disassemble, and clean vanes/unison ring.

- Replace with updated unison ring or aftermarket billet versions that resist sticking.

Prevention:

- Regular maintenance of the EGR system.

- Frequent hard pulls (load the engine) to help keep vanes clear and moving freely.

- Use of high-quality oil with frequent changes to reduce the buildup of carbon deposits (aka coking).

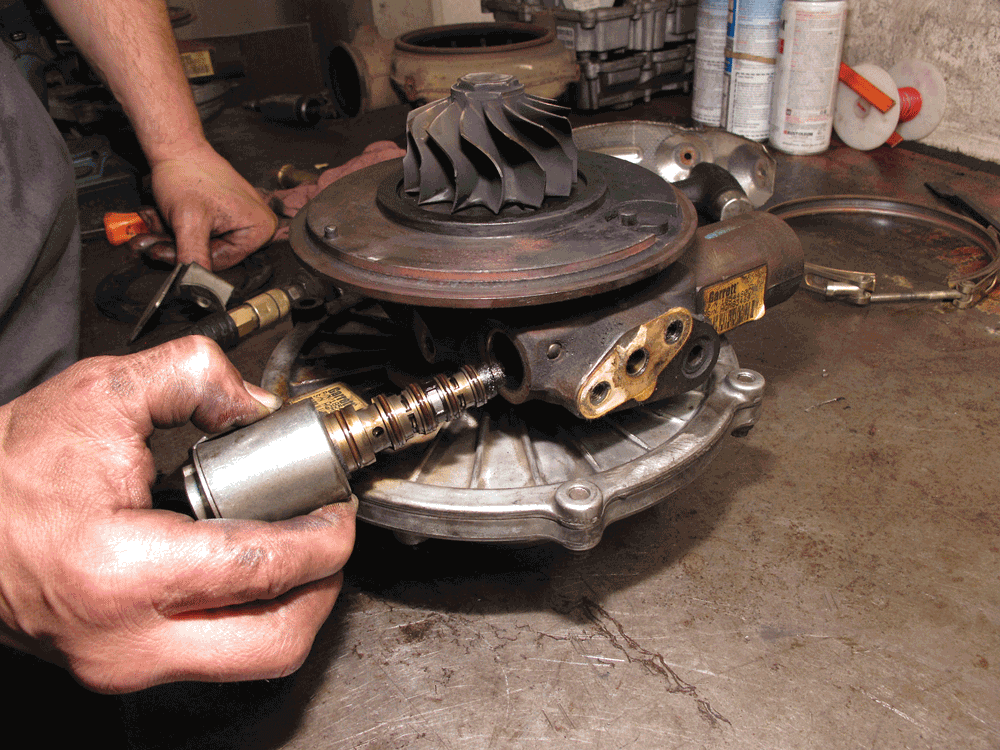

2. Turbo Vane Actuator / Solenoid Failure

This is the solenoid that physically moves the unison ring, controlling the vane position. It’s controlled by the PCM and relies on oil pressure to physically move the unison ring.

Cause: Electrical or mechanical failure of the VGT control solenoid.

Symptoms:

- No turbo whistle (vanes default to a fail-safe position)

- Limp mode with DTCs like P0299 (underboost)

- Erratic boost pressure spikes

Fix:

- Replace VGT solenoid with OEM or quality aftermarket unit.

- Check wiring harness for chafing or corrosion.

Prevention:

- Keep connectors sealed and clean.

- Use of high-quality oil with frequent changes to reduce the buildup of carbon deposits (aka coking).

- Replace early if erratic behavior begins—don’t run it until full failure.

3. Sticking or Seized Bearings (Oil Side Failures)

As with all turbos, the center housing bearings, which allow the compressor and turbine to spin freely, are detrimental to turbo performance.

Cause: Oil coking from extended idling, poor oil quality, or a restriction in flow.

Symptoms:

- Excessive turbo lag

- High-pitched whining noise increasing with RPM

- Shaft play detected when inspected

- Sudden turbo failure, sometimes with smoke and oil consumption

Fix:

- Rebuild or replace the turbocharger.

- Inspect and clear oil feed and drain lines.

Prevention:

- Use of high-quality oil with frequent changes to reduce the buildup of carbon deposits (aka coking).

- Avoid hot shutdowns and let the turbo cool after towing/hauling.

4. Compressor Wheel Damage / Surge (less common)

Damage to the compressor or turbine wheels themselves. Often comes with bearing damage too.

Cause: Foreign object ingestion (dirt/debris), overspeed from a cheap tuner, or surge from improper vane control.

Symptoms:

- Whistling or grinding sound from compressor wheel (FYI, the common whistle 6.0’s make which is normal, is from the turbine wheel and is most common with the 2003.5 turbo)

- Visible blade contact with housing

- Low or erratic boost pressure

Fix:

- Replace compressor wheel or, more commonly, rebuild or replace the turbocharger.

- Clean intercooler and piping of debris.

Prevention:

- Always run a quality intake/air filter system.

- Don’t run excessive tunes without supporting airflow mods.

- Monitor boost with a gauge and back off if surge is detected.

5. Overboost / Underboost DTCs (P0234, P0299)

Cause: Combination of issues: sticky vanes, bad solenoid, exhaust leaks, or faulty MAP/EBP sensors.

Symptoms:

- CEL with codes P0234 (overboost) or P0299 (underboost).

- Limp mode with reduced power.

- Black smoke under throttle (underboost) or white smoke/whistling (overboost).

Fix:

- Diagnose root cause: clean turbo, replace solenoid, check sensors.

- Repair boost leaks or exhaust manifold leaks.

Prevention:

- Keep sensors (MAP, EBP) cleaned and functional.

- Inspect CAC boots and clamps regularly.

6. Exhaust Leaks at Turbo Mount / Up-pipes

The pipes that feed the turbo on the exhaust side. Leaks mean the turbo can’t take advantage of exhaust pressure to spool the turbo.

Cause: Failed turbo mounting hardware, warped up-pipe bellows, or cracked manifolds.

Symptoms:

- Loud hissing or “jet engine” sound under load.

- Low boost / high EGTs.

- Visible soot around turbo or up-pipes.

Fix:

- Replace up-pipes with upgraded bellowed versions.

Prevention:

- Use quality hardware and gaskets on reassembly.

- Upgrade to aftermarket bellowed up-pipes (common reliability fix).

Things to keep in mind for VGT longevity:

- Oil Discipline: High-quality synthetic oil, changed on time.

- Exercise the Turbo: Avoid babying—periodic full-throttle runs keep vanes free.

- Sensor & Solenoid Maintenance: Keep MAP, EBP sensors, and the VGT solenoid in good shape.

- Air Filtration: Always run a proper intake with filter; never run an open intake without protection.

- Cooldown Practices: Idle the engine for 1–2 minutes post heavy towing/hauling/racing.

Helpful Links:

Full VGT diagnostic how-to from ID Speed Shop: https://idspeedshop.com/id-speed-shop-news/ford-60l-powerstroke-vgt-turbo-operation-and-diagnostics/

The 6.0L Powerstroke "Bible". Something every 6.0L owner should have (download): https://www.ford-trucks.com/ford-manuals/2003.25-6.0L%20CoffeeTableBook.pdf

6.0L Turbocharger related parts: https://www.riffraffdiesel.com/turbo-related-3/